Effective spare parts inventory management comes with several important organisational benefits. The following are worth considering when implementing CMMS management software in your manufacturing plant or factory.

- Reduced inventory costs

- Improved productivity

- Maximum operating reliability

- Fewer disruptions to processes, including the supply chain

- Reduced obsolete and duplicate materials

- Enhanced part visibility

- Improved equipment uptime

We’ll look at each of these benefits in more detail below.

1. Reduced inventory costs

Inventory comes in the form of the right parts and consumables that manufacturing plants require for greater machine efficiency. When an optimal amount of inventory is managed from a central location, such as a CMMS, costs are reduced.

This occurs because there is no overstocking (which leads to waste) or stockouts (which can result in high transportation costs, especially during emergency repairs). Other costs to consider include administrative and storage costs.

On the one hand, the less work your admin team needs to do ordering and managing spare parts, the more productive they will be elsewhere in your organisation. On the other hand, a minimalist and optimally-organised warehouse means fewer storage costs and streamlined operations.

2. Improved productivity

Even a single malfunctioning machine in your plant can result in a domino effect that halts the production process. The longer the time spent on repairing that machine, the longer your production process will be halted.

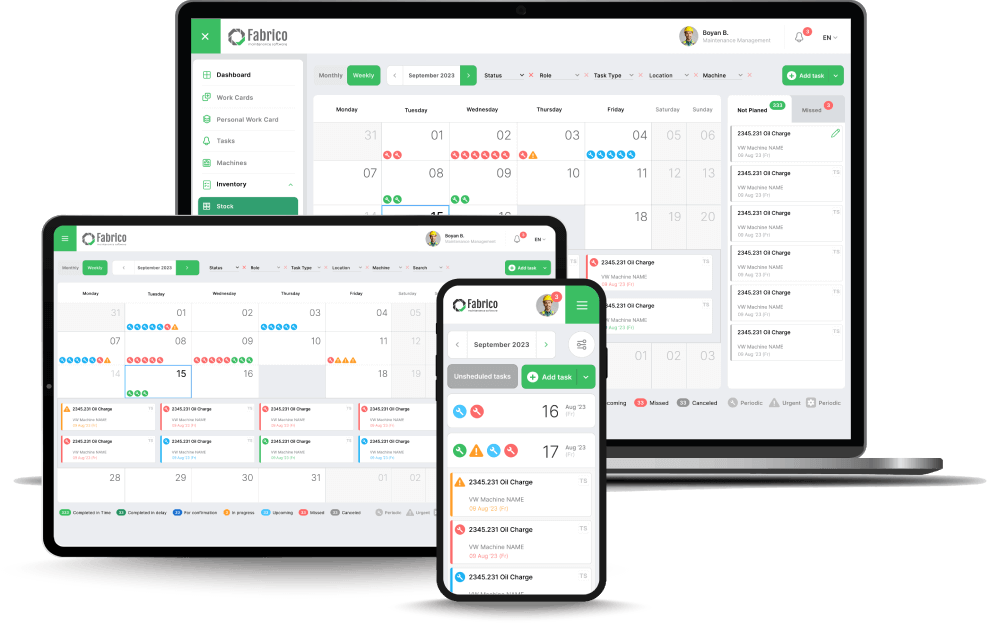

With effective and centralised inventory management, the right spare part can be accessed and fitted during preventive maintenance efforts. This can lead to fewer breakdowns and interruptions in production processes, thus ensuring minimal disruptions through parts that are readily available and easily accessible.

Your organisation’s productivity will improve when your production process is smooth and efficient, as the need for repairs and maintenance will decline with proper spare parts management.

3. Maximum operating reliability

A further benefit of spare parts management is that it leads to fast and efficient repairs or maintenance of your machines. When properly maintained at the right time, well-functioning equipment becomes more reliable.

This means you can enjoy greater predictability in your operations and have your production facility operate at maximum capacity. Overall equipment performance, reliability and longevity will minimise disruptions and maximise operational efficiency.

4. Fewer disruptions to processes, including the supply chain

If you find that you’re regularly ordering parts for the same machine, this situation requires careful evaluation of what the issue is. It could signal a need to reevaluate your maintenance and repair processes because persistent efforts with limited results can affect your supply chain operations.

This task can be made much more manageable with an inventory management system, which gives you a consolidated view of your operations. Consequently, you will be better positioned to anticipate supply chain needs and make real-time adjustments as needed.

When you know which parts are being ordered and used, it’s possible to establish patterns that can pinpoint issues in your production line and supply chain.

5. Reduced obsolete and duplicate materials

A spare parts inventory management system can help you reduce the number of obsolete and duplicate materials in your spare parts inventory. When a new part arrives, it is scanned and ordered in the right place.

It’s also possible to monitor inventory levels and order parts before they completely run out. This means that you can avoid purchasing duplicate parts when you already have sufficient stock of them in your warehouse.

This way, you’ll ensure that every spare part is visible in the system. What’s more is that obsolete parts can be recycled or removed from inventory, keeping your warehouse or stockroom minimalist but with all the necessary spare parts on hand.

6. Enhanced part visibility

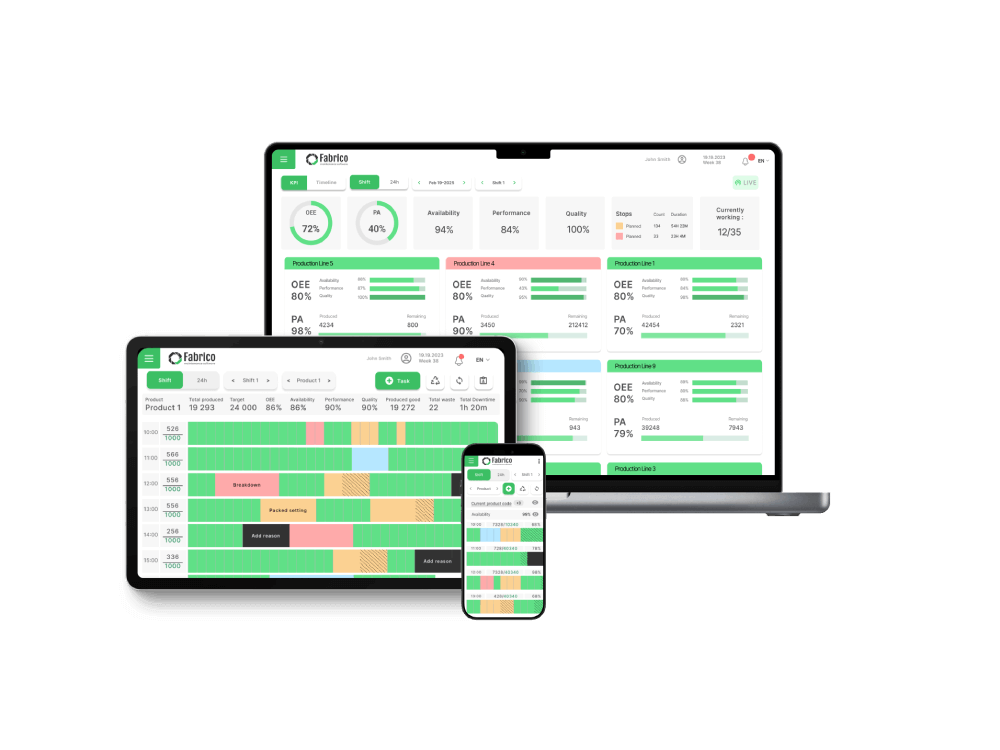

With the right CMMS software implemented in your operations, you can manage accurate spare part stock levels to ensure your organisation’s needs are met. Here, you can control and track entry and exit points for each spare part, allowing you to create an inventory control system that’s more precise.

You’ll have greater visibility and control over what spare parts you currently have and what your maintenance team requires. With an inventory that is easily managed, you’ll have all the parts you need when you need them the most. Making timely part replacements can help you minimise machine breakdowns.

7. Improved equipment uptime

By reducing the time it takes to carry out preventative maintenance or repair tasks, spare parts management can also help improve equipment reliability and, therefore, uptime. Machines that break down often can have a meaningful impact on productivity and profitability.

Such downtime can result in lost revenue, missed deadlines and reputational damage. When issues are identified before they become critical, spare parts can be replaced during planned maintenance so that unexpected failures can be avoided. Fast repairs with readily available spare parts can minimise repair time and maintain productivity.