IoT data is transforming the manufacturing industry as we speak. Here are 7 key ways IoT devices can help reduce unplanned downtime in manufacturing:

1. Real-Time Data Monitoring

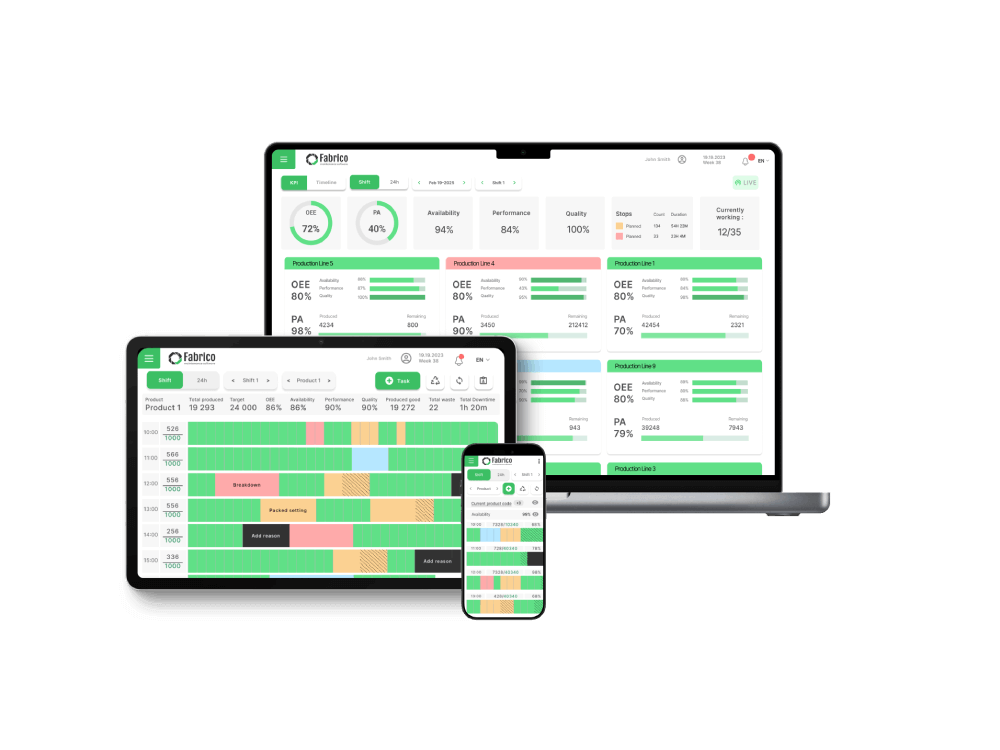

IoT sensors and devices continuously monitor equipment performance indicators in real time, such as temperature, vibration, pressure, energy consumption and other parameters. Any deviations from normal operating conditions trigger alerts, allowing maintenance teams to address issues and prevent unexpected downtime quickly.

Real-time monitoring with IoT devices plays a vital role in adopting a culture of continuous improvement within manufacturing plants. By tracking maintenance key performance indicators, teams can identify areas for optimisation, implement corrective measures instantly and improve operational efficiency.

2. Data Analytics

Data from IoT devices helps manufacturers analyze patterns, foresee potential failures and inefficiencies and make informed decisions to minimise downtime and maximise uptime. The insights derived from the collected data also empower decision-makers to implement data-driven strategies. By analyzing trends and patterns, maintenance managers can improve processes, avoid production disruptions and enhance overall equipment effectiveness.

3. Predictive Maintenance

Data generated by IoT devices can be used in predictive maintenance for manufacturing. The analytics algorithms process historical and current data to identify abnormalities and signs of potential equipment failures. The gathered information is useful for scheduling maintenance works before breakdowns occur, which leads to reducing unplanned downtime. Thanks to predictive models, manufacturers can apply a proactive approach towards maintenance operations based on machine health insights.

4. Remote Diagnostics

IoT devices also enable remote access to equipment statuses and performance data. This allows technicians to monitor operations from anywhere, without being physically present on-site. They can also diagnose problems remotely and take corrective actions on time to prevent machine downtime.

Monitoring and troubleshooting equipment from a distance reduces the need for on-site visits. This leads to shorter response times to maintenance issues and a quicker reaction to equipment malfunctions. In the event of a critical issue, remote diagnostics facilitate the immediate notification of the responsible maintenance personnel. All of these benefits contribute to downtime reduction.

5. Automation

IoT sensors can respond to environmental conditions, machine statuses or production metrics to trigger automated actions. This prevents breakdowns and malfunctions and minimises downtime in manufacturing plants.

For instance, sensors detecting temperature variations in a machine can automatically adjust cooling systems to maintain optimal operating conditions. By leveraging sensor data to make real-time decisions, IoT devices can autonomously execute tasks like adjusting settings or activating protocols to enhance performance.

6. Optimised Workflows

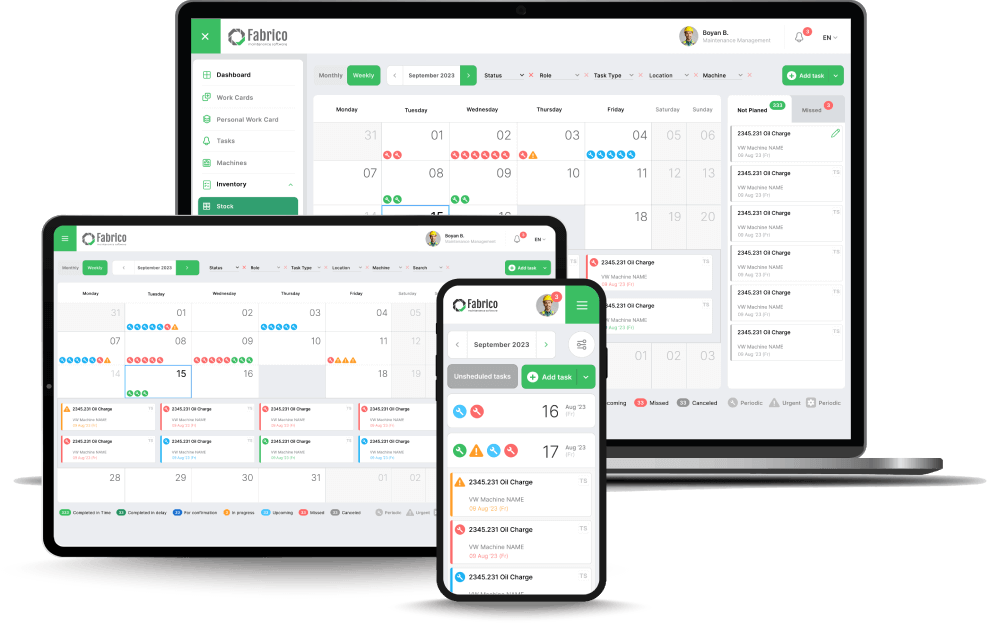

IoT devices can automatically perform routine tasks after programming based on predefined schedules or triggers. For example, sensors embedded in equipment can autonomously initiate maintenance routines at regular intervals, such as lubrication or calibration processes, without the need for manual intervention.

By setting up automated schedules, manufacturers ensure that repetitive tasks are carried out consistently. Such automation streamlines workflows, production schedules and resource utilization. It also minimises human errors and bottlenecks that can lead to downtime.

7. Supply Chain Management

IoT devices facilitate inventory level tracking and supply chain logistics management. Having spare parts and raw materials at hand when needed reduces the risk of downtime caused by stockouts.

Furthermore, IoT devices enable real-time monitoring of inventory and provide accurate data on demand fluctuations and consumption patterns. This allows manufacturers to optimise inventory and spare parts management by ensuring the right products and supplies are available at the right time and place.