Implementing predictive maintenance involves sensors that monitor machine conditions and IoT devices that collect real-time data. The information is processed by machine learning (ML) algorithms and artificial intelligence (AI) models to identify patterns and anomalies that may lead to malfunctions and production delays. Having a predictive maintenance strategy allows the maintenance team to analyze correlations between current and previous states and predict potential failures.

However, before getting there, manufacturing plants have to address these common challenges:

1. Adoption requires a change

The idea of relying on predictive models can be new to some production plants. Applying such models calls for a change in the way processes are handled. And people are often receptive to change, as long as they are part of the process.

For example, employees in a plant can give feedback on what would make it easier for them to use the new software, identify opportunities to improve data management or feel responsible for implementing the program. Thus, they’ll accept the changes more easily.

Adopting predictive maintenance technology requires a change in culture, which usually begins with a handful of enthusiasts who are naturally receptive to the new.

2. Perceiving predictive maintenance (PdM) as a quick fix

By implementing a predictive maintenance system you're playing the long-term game. Gains come with time.

There is a false perception that the easiest way to reduce maintenance costs in any plant is simply to optimize the number of employees and reduce the number of teams. The consequences of such short-term maintenance management can be devastating to total costs, and problems begin to appear after a year or two due to poorly maintained assets.

Changes in maintenance costs are related to both the quality of activities and production. Improving equipment reliability will reduce costs, but reduced costs will not improve reliability. Maintenance costs cannot be reduced quickly because it takes time to improve equipment reliability.

3. More maintenance staff doesn't equal reduced downtime

Hiring new technicians is not directly proportional to solving maintenance problems.

For example, if you have a large number of emergency repairs, you apply reactive maintenance – you repair the equipment after a malfunction happens. However, this approach doesn't lower the number of emergency repairs and the downtime that may occur because of them.

On the other hand, the main benefit of predictive maintenance is to foresee such mishaps before they happen and alert the maintenance department about them.

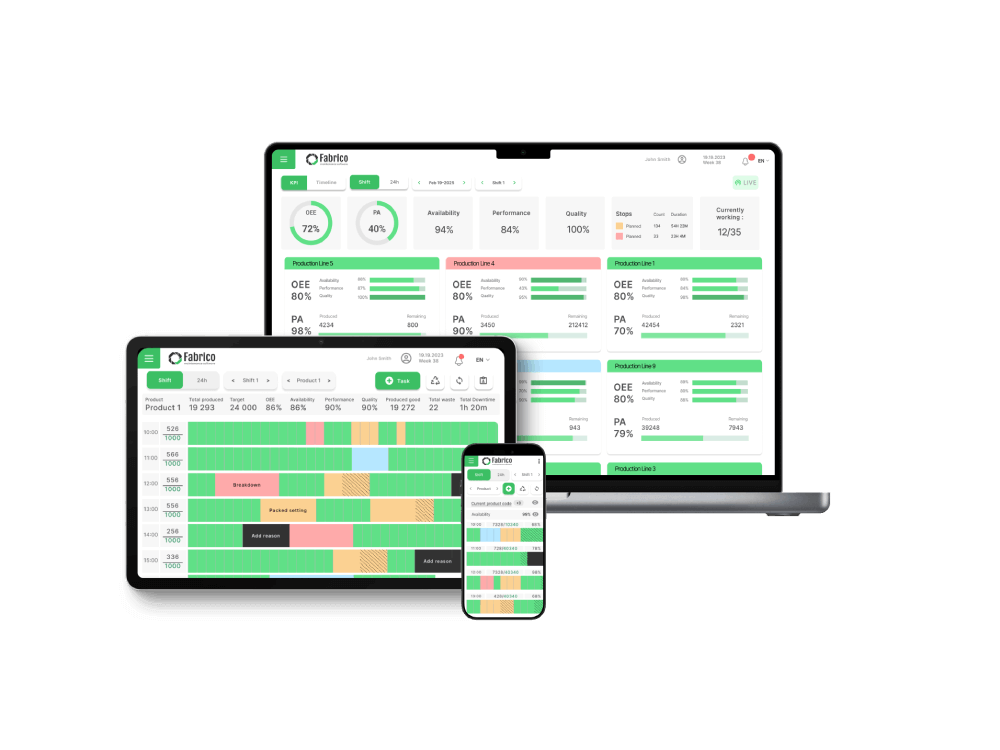

Without a maintenance management system, employees wouldn't be able to monitor large amounts of data and analyze trends to identify equipment problems. But implementing a predictive maintenance program would inform them when to schedule maintenance based on data analytics.

4. Shifting to paperless records

It takes an average of 12 minutes for a technician to look for information about past service in physical records and 4 minutes to report a maintenance activity on paper. And these are just a few of the service processes that are recorded on paper.

Using a predictive analytics system automates all these tasks and saves time that technicians can spend on the actual maintenance and repair.

Most organizations believe that moving to a paperless solution will cost more in terms of purchasing new software, hardware, and training. However, after the initial investment, companies typically realize their full return within the first 18 months.

5. Influx of equipment failures after launch

Many maintenance managers make the mistake of activating the predictive maintenance program all at once after everything is properly connected, without considering the associated processes and procedures.

This often leads to a flood of alarms and work orders that overwhelm maintenance teams. Addressing numerous new alerts can result in overlooking critical failures. This potentially can lead to unfavourable consequences for the program's success because of the maintenance team's discontent and their reluctance to use it.

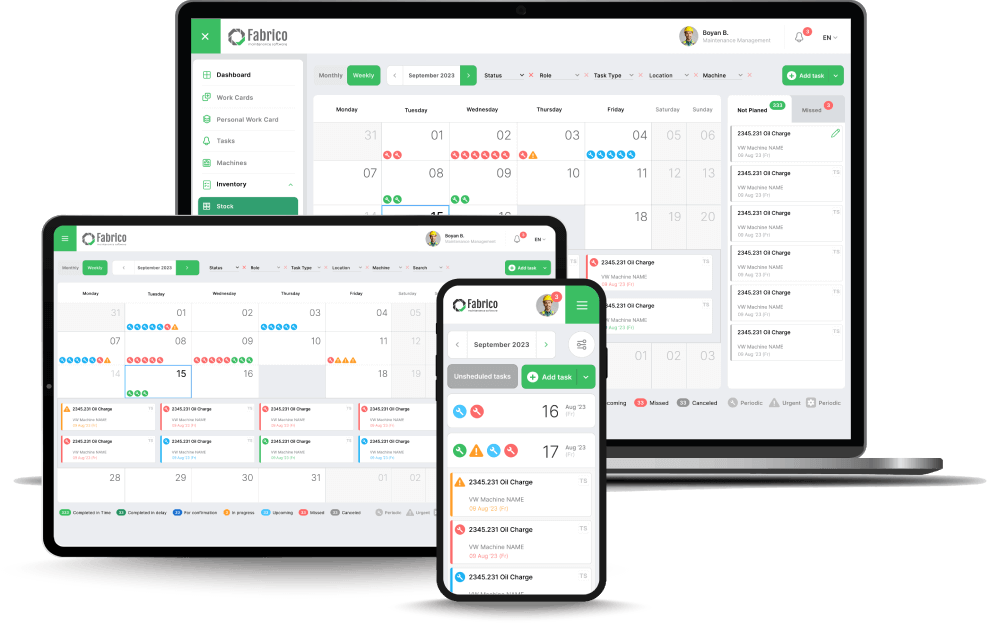

This challenge can be overcome by setting priorities in the predictive maintenance software. Thus, the system will automatically load the most critical ones upfront so technicians can address them in the proper order of importance.

6. PdM software is just a tool, not a universal cure

Manufacturing organizations must keep in mind that adopting a predictive maintenance solution is not a universal cure to production reliability. It's just a tool, a very useful one, but it can't improve the plant's reliability by itself.

If plant productivity improves after a change in software, the credit goes to the synergistic effect of implementing better workflows, changes in employee behaviour, and higher-quality software data.

Sometimes, maintenance software adoption becomes cumbersome, resulting in low use of the system. Some employees may be reluctant to accept it, and it is useful only when everyone's on board and receptive. This issue can be resolved with more detailed training, especially for the older staff, and being patient with the maintenance workers until they learn how to use it properly.

7. Lack of experienced personnel

A key benefit of predictive maintenance is its ability to replicate and scale the intuitive approach of experienced maintenance professionals. A skilled technician can identify unusual machine sounds or abnormal pressure gauge readings. The loss of institutional knowledge due to valuable employees' retiring only highlights the role of AI in addressing this challenge.

However, the purpose of AI is not to replace the expertise of maintenance engineers but to reduce the manual workload needed for successful maintenance. Amid labour shortages and growing production demands, it is crucial to enhance maintenance teams' resources. This enables them to focus less on manual record keeping and basic analysis, and more on addressing the actual issues in a plant.