There are numerous incorrect ways to handle work order processes, not least of which is the continued use of archaic paper-based systems. However, by following some industry best practices, you can significantly improve and streamline your organisation’s repair and maintenance processes.

Below are just a few of these top tips to assist in creating more efficient operations.

Provide onboarding training for employees

Machines and equipment are not perfect and will start malfunctioning or breaking down. You need to employ preventive maintenance strategies to ensure that these problems are minimised. For this purpose, make sure that your employees can identify problems before they arise and also have access to the right communication channels to report such issues.

This is where onboarding training comes in. Teaching your employees how to use a CMMS ensures quicker navigation through the system and seamless workflow afterward.

The training process is easy and requires following a few simple steps in the CMMS interface:

- Identify the various user roles that will be a part of your work order management process.

- Assign work and responsibilities.

- Have a clear chain of command to know who is responsible for what and when.

Establish a centralised workflow

In the days of paper-based task management processes, it was common for the paper to float in and around filing cabinets and desks, thus easily getting lost or misplaced. Today’s landscape is much different.

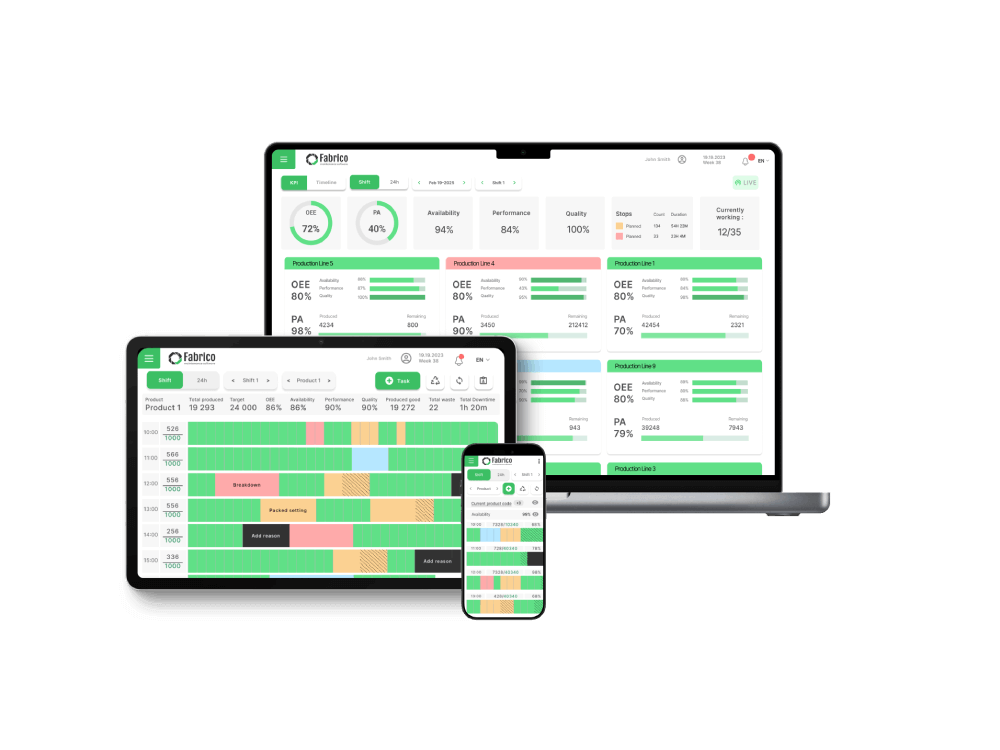

With the rise of technological developments, creating centralised workflows through an effective CMMS is much easier. These workflows are digitised and can send updates to the relevant technicians in real time through internet connectivity on mobile devices.

This means that individuals assigned to the work order will be well positioned to ensure that maintenance and repair tasks are part of a streamlined pipeline or workflow. As such, it becomes much easier to operate from a central location that distributes different types of work accordingly, as opposed to managing and keeping track of paper-based systems.

Delegate tasks effectively

Every machine in operation at your manufacturing plant needs a specific set of skills for accurate repair and maintenance. This means that you need the right team members assigned to the right machines and tasks.

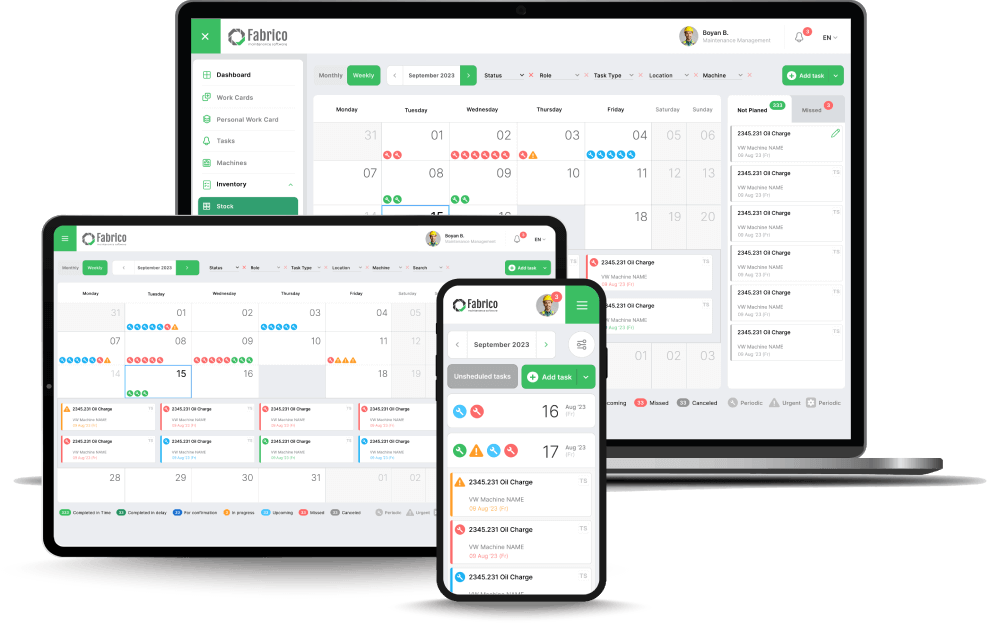

This is where delegating tasks effectively comes into play. Luckily, with a CMMS at your disposal, you can do so in advance while ensuring that your digitised message with instructions is sent to the right technician. This small action gives them enough time to complete their work.

Maintenance managers also need to take into account an efficient distribution of the workload for their teams. This is necessary because some technicians may be overloaded with work orders while others may remain idle. Work orders should also help technicians carry out their tasks.

This means that the right asset needs to be identified; the problem or service needed should be described as well as the parts and tools that are required for the job. In addition, it will be necessary to create a task checklist, provide any relevant documentation and add notes, where needed.

Ensure all requests start with a work order

Work order requests are the predecessors of work orders. In practice, these requests are created either by a maintenance technician or a maintenance manager.

However, very frequently, individuals outside the maintenance department create work order requests through a maintenance request portal.

This portal is usually the standard channel for submitting requests for maintenance work. As a best practice, these requests should be submitted formally and they should precede a work order being created. It is essential that everyone using the system knows how to submit requests that contain useful information to help a maintenance technician carry out their job optimally.

With CMMS software, it’s possible to identify a designated system administrator who can indicate all the required information prior to the maintenance request being accepted. This can be expedited by a maintenance manager with the requisite authority to approve the request and move it forward for execution.

Set work order priorities

Once a work request has been transformed into a work job, it’s important to realise that these requests can come in batches. This means that your team of skilled technicians may be spread quite thin in terms of carrying out these jobs at the same time.

This is why you should prioritise your work tasks. Maintenance managers should create a set of prioritisation guidelines and then follow these to make the best decisions. Often, assets that are considered critical or time sensitive should be prioritised. It’s also imperative to prioritise tasks that minimise safety risks. Examples of the types of priorities that may be used include emergency, high, safety, medium, or low.

Having some of these criteria in mind ensures that tasks are prioritised accurately and for the best of the organisation.

Grant resource accessibility

Many maintenance work orders require resources—from consumables to tools and equipment—to effectively carry out the job. However, if your inventory management system, from which you need to source materials, is not in order, the chances are that you will be working with a complex system that your team will be unable to navigate.

Using a CMMS can help you manage your inventory better and ensure that all the right stock and spare parts are allocated to the right job. In addition, it can help you manage inventory levels so that when stock or spare parts run low, you will receive a notification.

Once you have this system in place, you will be able to grant access to the right team members with the right levels of access to your organisation’s resources. This is a best practice that can significantly streamline your operations.

Develop task checklists

Making sure that you or the right team member develop task checklists is another essential best practice. Checklists set out the different aspects of the work order that need to be completed, often in a particular order.

Through these checklists, you can have greater confidence in your team of technicians. Ticking each item off the list means that the chance for human error is reduced and there will be optimal utilisation of time and resources.

Checklists should be comprehensive and detailed, and they should set out each activity that needs to be carried out before the task is considered closed.

Transition from paper-based processes to digital methods

There are significant benefits to transitioning from paper-based processes to digital methods, such as CMMS management software. With such a system at your disposal, you’ll be able to avoid searching for missing files and cease manual administration and paperwork.

The ultimate goal is to save time and avoid pitfalls such as lost papers, missed signatures or forgotten jobs. Managing and tracking these becomes so much simpler with easy generation and tracking to ensure nothing slips through the cracks.

In fact, it’s been proven that using a CMMS can help reduce equipment downtime and material costs, making this practice a worthwhile endeavour.

Thoroughly document each step

Another leading practice is monitoring your documentation because it lays the foundation for accurate reporting.< span>

When you have quick and convenient access to the number of jobs completed, the time it took to complete the work, the cost of the materials that were used, the team members involved, etc., you can track key performance indicators (KPIs) much better than through a paper-based system.

It often happens that managers find themselves spread out all over the maintenance facility as new problems arise. So, it’s essential that every step is documented through a digitalised work order management system to accurately catch all the data that is being processed and produced.

Utilise work orders to monitor inventory

Utilising a work order management software to help you handle your work orders is also an effective way to manage and monitor your inventory.

All the resources that go into a job can be automatically tallied. Keep the system updated so that better and more informed decisions can be made regarding your spare parts and inventory.

To make the most out of your inventory monitoring, a frequently encountered top industry practice is to ensure that your chosen CMMS incorporates inventory monitoring and management as part of the work tasks.

Collect and analyse data effectively

A task management list of top practices would be incomplete without mentioning effective data collection and analysis. Ultimately, data collection and analysis are very useful and important to help you make more informed decisions.

This helps with accurate reporting, which is often a legal requirement, and it assists with record-keeping, analysing inefficiencies, setting goals, and adapting jobs to meet them. Data metrics you could gather and use include service histories, warranty information, part lists, employee scheduling data and more.