The costs is calculated for an average manufacturing plant based on а study conducted by ABB among 3215 managers from multiple manufacturing industries.

Through improving operational efficiency, the production capacity and production output can grow significantly.

Through empowering effective asset maintenance, you can gain control over downtime.

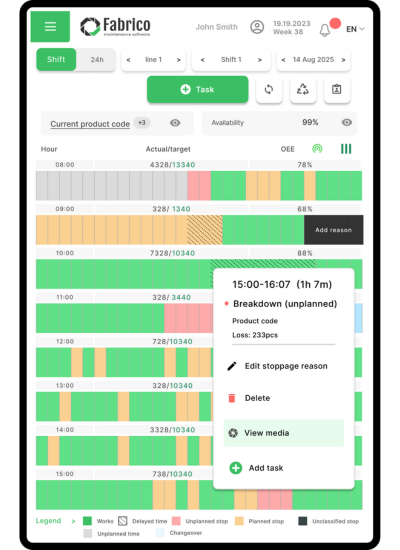

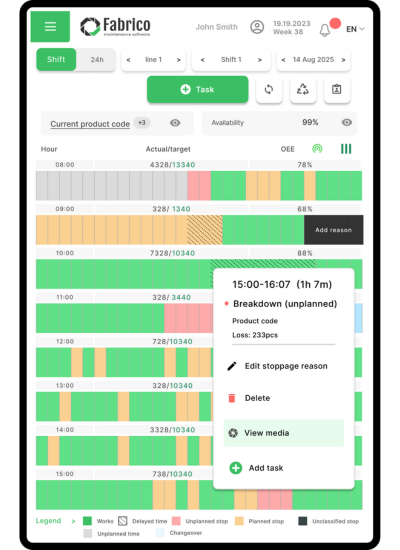

Using our intuitive mobile application is exceptionally straightforward. Our adaptive design ensures complete accessibility across all devices, featuring user-friendly task scheduling and clear reporting visualizations. Additionally, our dedicated iOS and Android apps provide seamless plant management on the go with just a tap.

Effectively handle, modify, and assign work orders from the field. Generate work orders from your desktop and send them directly to your team on the factory floor. Stay informed with push notifications for critical updates, ensuring you're always in the know.

Fabrico's web app is its intuitive interface, which simplifies the complex processes involved in maintenance management. With a comprehensive dashboard, users can view scheduling and reporting data in real time, allowing for efficient planning and execution of maintenance activities.

The web version of Fabrico is a powerful tool that enhances the efficiency and effectiveness of maintenance management. Its user-friendly design, coupled with robust visualization and reporting capabilities, makes it an indispensable asset for any organization looking to streamline their maintenance processes and improve asset reliability.

Fabrico CMMS takes maintenance management to the next level with its integrated QR code scanner feature for machines and spare parts. This tool enhances the efficiency of tracing maintenance activities and spare parts management, ensuring that information is accurate and easily accessible.

QR codes serve as a quick and efficient method for recording and retrieving data related to maintenance tasks. Each machine and spare part can be tagged with a unique QR code, which, when scanned, provides instant access to detailed information such as maintenance history, usage statistics, and part specifications. This eliminates the need for manual data entry, reducing the risk of errors and saving valuable time.

Fabrico connects any machine — new or legacy — using PLCs, IoT sensors, or cameras powered by AI. Our modular connectivity approach ensures no production line is left behind.

1. Existing Machine Connectivity (PLCs)

For machines that already have connectivity

2. IoT Device with External Sensors

For machines with limited connectivity

3. Production Output through Camera/AI

For cases where sensors can’t collect data

"My favourite aspect of this software is how simply work orders can be created, labelled, allocated, and followed through to completion. This makes it possible to guarantee that urgent issues are resolved quickly.”

"Our team quickly adapted to Fabrico's platform. It was easy to use, and the benefits were evident almost immediately. The best feature for us is the real-time information about our machines and technicians. We now know exactly what's happening at any given moment, which has significantly increased our productivity."

The shift from manual to automated systems not only improved daily operations but also provided strategic insights that drove better decision-making at all levels of the organization.

The task management features allow us to organize our workflow efficiently, ensuring that every maintenance activity is accounted for and completed on time. This level of organization is crucial in preventing machine breakdowns and maintaining our production schedules.

"Fabrico has revolutionized our factory operations! Downtime is down by 40%, staff productivity is up by 30%, and our processes run smoother than ever. A game-changer for efficiency and cost savings!"

The main factor to choose Fabrico over other similar products was the great value for money. Since beginning of the implementation process, the Fabrico team have been extremely supportive, quick in responding and open to any suggestions, criticism or requests for customisation we've had!

Fabrico team was very reactive and we managed to integrate the solution in a week. Users were onboarded quite fast and after a short demo they feel confident to start using it ona daily basis.

"Downtime has significantly decreased, and our technicians can now respond to issues faster thanks to smart notifications. The system’s ease of use and real-time tracking have made maintenance management smoother and more efficient. We couldn’t be happier with the results!"

The regular support and training from the Fabrico team have been invaluable in maintaining our high standards.

"Starting with Fabrico at the very beginning of operations allowed us to create a complete database of equipment performance. This has provided invaluable insights, helping us optimize maintenance schedules, prevent issues, and extend the lifespan of our machinery."

"We were hesitant at first because of the time required to implement Fabrico, but the results have been worth it. The support from Fabrico’s team was exceptional, and now our productivity has increased, and our team is more efficient than ever. The smart notifications alone have made a huge difference."

"I no longer have to spend hours in meetings or chasing information. Everything I need is just a click away. This has allowed me to focus on the bigger picture, knowing that the data is reliable, and downtime is minimized. It’s a game-changer for our industry."

"The ability to track repairs and respond to issues in real-time has been a game-changer for us. We’re now more confident in meeting our production targets and delivering on our promises to customers worldwide."

"Our machines run better, our team is more efficient, and I can manage everything in real time."

"What used to be a chaotic process of juggling Excel sheets, paper notes, and memory is now an efficient, real-time system. Our technicians are better informed, our managers have full visibility, and machine downtime has significantly decreased. Fabrico didn’t just streamline our operations—it gave us the tools to focus on innovation and growth."

Technicians across the plants reported consistent improvements in their workflows and reduced frustration with maintenance tasks.

Cameras act as an additional visibility layer in Fabrico’s OEE system — capturing the human and process context that sensors or PLC data alone can’t provide. Combining machine + human interface + camera data allows Fabrico to move from partial to full visibility.

Our platform establishes a single source of truth for OEE data by integrating directly with your PLCs and IoT sensors, engaging people in the loop and covering the invisible inefficiencies through computer vision over the line. We move beyond manual data entry to provide validated, real-time metrics for the three factors:

Fabrico’s CMMS and EAM deliver fast, measurable ROI by turning maintenance into a driver of uptime and efficiency.

Yes. Our platform is engineered for multi-site enterprise asset management (EAM). The central web platform allows corporate teams to standardize asset hierarchies, create master PM templates, and deploy standardized digital work instructions across all facilities instantly. This standardization ensures data consistency for benchmarking and guarantees every site operates using the same, proven best practices for maintenance and compliance.

Seamless integration is a non-negotiable feature for enterprise clients. We provide a robust integration ecosystem (APIs) to ensure bidirectional data flow with your ERP for Total Cost of Ownership (TCO) reporting, automated MRO inventory synchronization, and finance reconciliation. Direct integration with the OT layer (PLCs, SCADA) guarantees the real-time, accurate data required for our OEE calculations.

We prioritize rapid deployment with minimal operational disruption. A pilot site can be operational in days, followed by an enterprise-wide rollout in a structured number of weeks. Due to the highly intuitive, consumer-app-like user interface, the training footprint is minimal, allowing for accelerated user adoption and compliance across your maintenance, operations, and quality teams.

Fabrico uses best-in-class security practices to maintain a high level of security. Security measures encompass a multi-layered approach to ensure the utmost protection of the client’s data and the smooth operation.

Security and auditability are foundational, especially in regulated industries. The system provides complete audit trails for every transaction, modification, and work order closure, ensuring full compliance with industry standards and internal governance. Our role-based access control (RBAC) ensures only authorized personnel can view or modify critical asset data, protecting the integrity of your CMMS records and financial data.

The solution and the company behind it hold ISO certifications for Information Security Management ISO/IEC 27001, IT Services Management 27001, and Quality Management System 9001

Our solution extends beyond day-to-day maintenance into full Enterprise Asset Management (EAM). By integrating with your ERP, we track all costs associated with an asset—initial purchase, labor, parts, and service contracts—from acquisition to decommissioning. This comprehensive view allows finance and reliability teams to accurately calculate Residual Value and make data-backed decisions on asset repair vs. replace strategies.

While OEE is critical, our advanced analytics dashboards provide deep visibility into dozens of core maintenance and reliability Key Performance Indicators (KPIs), including:

These insights empower Reliability Engineers to conduct effective Root Cause Analysis (RCA) and continuously optimize maintenance programs.

We eliminate the paper trail by digitizing and centralizing all critical documentation. When a technician scans an asset or accesses a work order on the mobile app, they instantly receive the latest, version-controlled SOPs, checklists, safety warnings, and high-resolution schematics. This guarantees work is performed correctly and safely every time, protecting both your personnel and the quality of your output.